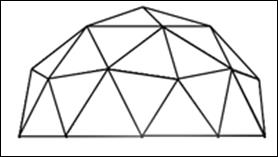

It all started with my brother Charles going to Burning Man with his 3V dome as described by Desert Domes.

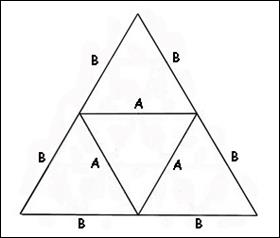

A 2V form was chosen for the

sphere. Standard, 120 inch, ¾” EMT

(electrical conduit), 3/8 by 1 ½ inch galvanized bolts, and 6 galvanized eye

bolts were used. The following tables show how strut lengths and weight were

calculated:

A 2V form was chosen for the

sphere. Standard, 120 inch, ¾” EMT

(electrical conduit), 3/8 by 1 ½ inch galvanized bolts, and 6 galvanized eye

bolts were used. The following tables show how strut lengths and weight were

calculated:

|

2V Sphere Calculations |

|||

|

Strut |

Strut factor |

vertex length (in) |

add 1.5" for junction margins for tube length |

|

A |

0.61803 |

40.044 |

41.544 |

|

B |

0.54653 |

35.412 |

36.912 |

|

radius (in) |

64.793 |

|

|

|

diameter (feet) |

10.80 |

|

|

|

length check (in) |

|

120.000 |

|

|

|

|||

|

algebra |

|||

|

2A+1B=120-(3*1.5)=115.5 |

|||

|

B=A*0.54653/0.61803 |

|||

|

2A+0.88431A=115.5 |

|||

|

2.88431A=115.5 |

|||

|

A=115.5/2.88431 |

|||

|

|

|||

|

dome radius = strut length/strut factor |

|||

|

WEIGHT CALCULATION |

|||

|

nominal lbs/100' |

46 |

||

|

strut |

count |

length (in) |

weight (lbs) |

|

A |

60 |

41.544 |

95.55 |

|

B |

60 |

36.912 |

84.90 |

|

total |

180.45 |

||

The instructions from Desert Domes were used to cut, shape, and drill the struts and bolt them together. It is a happy coincidence that the standard 10 foot EMT makes a 10.80 foot diameter sphere. This size is just right for a living space. Here are a couple of pictures of some of the details.

The stanchions and floor were sized by empirical measurement. The center floor panel is round and removable to accommodate entry and, if removed, to allow assembly around a tree trunk. The original center floor panel was a complete circle. It would not fit through any of the triangular openings after the sphere was assembled. It is now two half circles with a 1 inch hole to accommodate a rope hanging down the center. This center floor panel is the entrance.

All the A struts form 6 EQUATORS. None of these are parallel to the floor. One is highlighted in the left hand picture. The FLOOR and STANCHIONS are highlighted in the picture to the right.

The sphere was first hung by three PMI E-Z Bend Sport 11mm Non-Dry Ropes. They were wrapped around the tree and attached to the upper eye bolts of the sphere with screw links. This configuration is very wobbly. Every step causes the whole sphere to move awkwardly. Keeping one’s feet was a problem. Testing was done on a model using 6 lines and it is much more stable. Suspending the sphere from rope wrapped around the tree would damage the them in the long run. Research shows a fastener into the trunk is a much less harmful anchor. Tabs with D rings were attached to the trees with 6 inch by ½ inch lag bolts.

At Christmas, the sphere is decorated. My son Jon helps.

The sphere needs a cover to protect inhabitants. A completely transparent cover would allow a nearly 360 degrees view outward. However, clear vinyl is expensive, fragile, and gets dirty quickly. A waterproof tent material would be better. It too is expensive. Tarp and duct tape are cheap. Joints are simple. The edges of the tarp to be joined are butted together and taped on both sides. The resulting joint is stronger than the tarp. They were chosen as the materials most suitable for the first efforts to try out different designs. “Covering” the whole sphere would require accommodating passages at the suspension points; three upper and three lower, and seam joints to install over the sphere. However, a complete cover is not necessary. It just needs to be big enough to protect the floor from rain.

The current design attaches to the inside. At first, grommets were installed and the cover was attached to the protruding ends of the bolts. They are just long enough. This requires great precision and accuracy. The first few pieces fit well. As pieces were added, there was either stretching or bagginess. The attach system was changed to cord attached to the cover and tied at each joint. This system is more forgiving but has some bagginess.

The cover could be on the outside since it is partial cover. The current cover extends to the upper attach points so there is no need to make passages for the attach ropes. The cover needs to be just a bit bigger to completely cover the floor. Work on the inside cover will be abandon an outside cover will be made.

A new cover was made and stretched over the outside. It is attached at the lower points with ties. It extends beyond the perimeter of the floor so rain does not fall on the floor.

The top panel of the cover is parallel to the ground and would collect rain. The inside of the cover would collect cooking fumes, humidity, etc. This is an opportunity for a vent. One was made that attaches with spring force to the vertices of the top opening. The top panel is offset by about 3 inches and extends beyond the upper opening making a vent that prevents drips. The wooden ribs bend upward so the panel will shed rain.

The goal is to make an accommodation for about 3 people that can be assembled at a site and hoisted into the canopy. Light weight is important.

Here are the proposed changes and additions:

1. Use certified suspension grade eye bolts since stress is concentrated at the attach points.

2. Use certified suspension grade screw links.

3. Use rainproof tent fabric instead of tarp.

4. Add a net around the perimeter of the floor to prevent gear and people falling.

5. Make openings in some of the fabric panels on or near the top to peer out.

6. Make new floor that slopes outward for drainage. Center circle already has this.

7. Re-design floor to floor and floor to stanchion fit for easier, more forgiving assembly.

8. Add a curtain rod under the cover inside the sphere and curtains to keep rain and wind at bay. The bottoms of the curtains will attach to floor.

9. Put the cover on the outside of the struts. It leaves more room inside and allows for secure attach points at the ends of the bolts. An outside cover is supported by all the struts. Fewer attach points are required.

10. Maybe use cable instead of rope to reduce bounciness.

11. Sleeping can be done in hammocks or on the floor.

Here are some questions:

1. Most joints are bolted with 3/8 x 1 ½ inch galvanized coarse thread bolts. Should better bolts be used?

2. Are the tree attach points adequate?

3. What is the best fabric for the cover?

4. How do I make the openings in the cover?

5. Is it important to make the cover bug and critter proof?

6. Is having the entrance through the center of the floor going to work?

7. Is this something people would want?